by Xuegang Liu

Division of Nuclear Chemistry and Engineering The Institute of Nuclear and New Energy Technology

Tsinghua University, Beijing, China

5 August 2014

I. INTRODUCTION

With a population exceeding 1.3 billion and high economic growth averaging ~8% since the early 1980s, China’s demand for energy has increased dramatically. As of 2013, China is the world’s second largest energy consumer, behind only the United States, with consumption of 3.62 billion tonnes of coal equivalent (TCE) of energy in 2012.[1] Meanwhile, the energy consumption per capita in China is still small by industrialized-country standards, which means China’s high rate of increase in energy consumption will be ongoing for the foreseeable future.

In contrast to the current energy mix in many other countries, including the United States, Japan, and the larger nations of Europe, a key feature of China’s energy structure is its continued heavy reliance on coal, which accounts for around 70% of total energy production. Coal reliance has resulted in many problems in China, including the high human cost associated with coal mining, the severe burden on China’s transportation network of moving billions of tonnes of coal from mines to consumers, and the progressively more serious environmental pollution associated with coal production and use. With these drawbacks of coal dependence in mind, Chinese officials and businesses have for many years worked to reduce coal use. One major approach in recent years has been to develop nuclear power as a promising, low-pollution alternative to coal-burning power.

The first nuclear power plant (NPP) in China went into commercial operation in 1994. Following commissioning of the first nuclear plant, however, the development of nuclear power slowed until 2004, when the so-called “nuclear renaissance” caught the attention of power sector planners around the world. Since then, ambitious nuclear development programs have been proposed for China, and the targets of nuclear power capacity for 2020 were set to levels ranging from 40 GWe (gigawatts of electricity generating capacity) to 86 GWe, as estimated by different government and industry groups in China. Meanwhile, a large number of NPPs were under construction or in advanced phases of construction planning, such that the number of NPPs under construction in China account for around 40% of the world’s total. Following the Fukushima Daiichi nuclear accident in Japan, China’s prompt response was to halt all nuclear project approvals and start a comprehensive safety review of all operational and under-construction NPPs. After nearly two years of effort the State Council Standing Committee approved the Nuclear Power Safety Plan (2011-20) and the Nuclear Power Mid- and Long-Term Development Plan (2011-20) in October 2012. The State Standing Council Committee concluded that the nuclear development policy should emphasize “steady development with safety”, meaning an emphasis on more cautious approaches to nuclear development, with strengthening of safety as the primary consideration.

The Fukushima nuclear accident also increased concerns among the public and policymakers about the accumulated spent nuclear fuel in pools on NPP sites. As a result, spent nuclear fuel management in China received more attention, though the inventory of spent fuel in China is relatively small in comparison with other major nuclear countries such as the US, Japan, and others. The nuclear reactor fleet in China is and will continue to be made up of multiple nuclear reactor models, including M310, CPR, CANDU, AP1000, HTR and others, meaning that a number of different technical approaches in the management of spent fuel will be required. In the longer term, the closed fuel cycle concept has been chosen as the guideline for spent fuel management, with recycling of spent fuel as the ultimate goal. For short-term storage, wet pool storage is widely used in all nuclear power plants with PWR (pressurized water reactor) units, which are the most common nuclear reactor type in China. Dry cask storage has only been implemented for CANDU spent fuel at the Qinshan Phase III NPP, because of the low thermal density of CANDU spent fuel and the lack of plans to reprocess spent CANDU fuel, which is made of natural uranium. Dry cask storage is also a possibility for use in storing fuel from high temperature gas cooled pebble-bed reactors, and dry casks are being designed for this purpose.

This paper describes the recent trends and current status of nuclear spent fuel storage in China. The contents of the paper are as follows: (1) a brief introduction to China’s energy situation by way of background; (2) an overview of the status of China’s nuclear sector and the response to the Fukushima Daiichi nuclear accident in terms of China’s nuclear policy, regulation and programs; (3) a summary of the current status of spent fuel storage in China and a presentation of results of preliminary analyses of safety aspects of spent fuel storage at selected plants; and (4) remarks and conclusions.

II. THE ENERGY SITUATION IN CHINA

2.1 Primary energy and electricity production

With a population exceeding 1.3 billion and high economic growth averaging ~8% since the early 1980s, China’s demand for energy has increased dramatically in recent decades. According to the International Energy Agency (IEA), China has in recent years consumed more energy than any other nation. In 2012, China’s total energy consumption reached 3.62 billion tonnes of standard coal equivalent (TCE), compared to about 3.48 billion tonnes in 2011 and 3.07 billion tonnes in 2009.[2]

The structure of energy consumption by fuel in China has remained relatively unchanged over the past 30 years. The use of coal, the dominant fuel, accounted for around 69% of primary energy use in 2010, followed by oil (19%) and natural gas (4%). In contrast, the total primary energy provided by non-fossil sources (hydro, nuclear, wind, solar and etc.) only amounted to 8.3% in 2010.

- China is the largest producer and consumer of coal in the world, and accounts for almost half of the world’s coal consumption. With the third largest coal reserves behind the United States and Russia, China holds around 13% of world’s total coal reserves. China, previously a net coal exporter, became a net coal importer in 2009.

- China is the world’s second largest oil consumer behind the United States. The growth of oil consumption in China accounted for around half of the world’s total growth in oil use in 2011.

- China’s natural gas production and demand have risen substantially in the past decade, and China became a net natural gas importer in 2007.

China’s total installed electricity generation capacity reached 1.14 billion kW by the end of 2012, and its hydropower and wind power sectors boasted the world’s highest capacity. China’s electricity output hit 4.94 trillion kWh in 2012,[3] an increase of 4.52% year on year from 2011, according to the State Electricity Regulatory Commission. (Even at that, the growth rate was markedly lower than the 11.7% increase posted in 2011, echoing the slowdown in the country’s economy during 2012.)The structure of China’s electricity production is also dominated by coal, and electricity production from coal accounts for at least 78% of national total power generation. Hydropower accounts for around 16% of electricity output, followed by nuclear power (around 2%) and others (oil, gas and renewable energy). These fractions of output by fuel type are expected to remain relatively stable through 2020.

2.2 Need for nuclear power

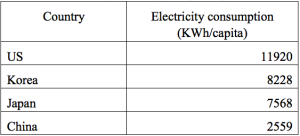

Although China’s energy consumption is large in absolute terms, the consumption per capita of 2559 kWh in 2012 is very small, as shown in Table 1, relative to that in the developed economies, at only about one fourth of the per capita consumption in the United States, and one third of that in Japan and South Korea.[4] This vast difference of energy consumption per capita implies great potential continued growth in electricity demand in China.

Table 1: Electricity consumption per capita in 2012

The heavy reliance on coal in terms of overall primary energy and as a fuel for electricity production has already resulted in a series of problems. China’s coal mining industry is the deadliest of the world in terms of human safety. Compared to around 30 deaths per year in coal mines in the United States, thousands of coal miners have been killed in accidents in coal pits in China each year in recent years. The heavy utilization of coal also places a burden on the transportation system due to the typically great distances between coal production areas and coal-burning power stations. Around 1/3 of primary energy is used in the transportation sector in China, and in turn half of railway transport capacity is used to move coal from mines to consumers. Moreover, severe environmental pollution is caused by coal transportation, storage and burning, including emissions of acid rain precursors, dust, and soot. In Beijing, atmospheric pollution has caused widespread worries because the announced ambient air pollution remained at the “unhealthy level” or worse almost every day from the start of the winter of 2012 through summer of 2013. The pollution index often soared off the charts in the spring of 2013. With the increase of environmental awareness among China’s citizens, concerns about pollution resulting from fossil fuel burning are more prevalent, and are being taken more seriously. The Chinese government and people recognize the urgency to reduce the nation’s heavy reliance on coal.

As a safe, clean and potentially renewable energy source, nuclear power has been regarded as an essential part of China’s future energy mix. Nuclear power is expected to play an important role in China’s future in helping to meet the increasing demand for energy, to adjust the coal-dominated energy structure, and to strengthen national energy security. Before the Fukushima Daiichi nuclear accident in 2011, the generally good operational performance of nuclear power plants in China and worldwide was also a strong evidence for China’s nuclear expansion.

III. nuclear development in china

3.1 Nuclear development before 2011

Though the decision to develop civilian nuclear energy in China dates back to the 1970s, concrete efforts to construct nuclear power plants (NPPs) began only in the late 1980s. The first commercial nuclear reactors in China came into operation in 1994. All of China’s nuclear power units have been installed and started operation since that time, thus the history of civilian nuclear development in China spans less than twenty years.

The development of China’s nuclear power was slow in its first decade, which is described as the period of “moderate development” for nuclear power. By the end of 2003, only eight units were in operation with 6.1 GWe of total installed capacity. China’s development of nuclear power accelerated from 2004, when the so-called “nuclear renaissance” became a topic of worldwide discussion. Between 2004 and 2011, five new nuclear units were commissioned in China, with total capacity of 4.2 GWe. More importantly, China’s national nuclear policy was changed from “moderate development” to “positive development”, which resulted in construction starting for a large number of NPPs, with planning for many more underway. By the end of 2010, twenty six nuclear units with total rated capacity of approximately 26.2 GWe were under construction, and thirty two further units had been approved. The different planning authorities with jurisdiction over the nuclear sector announced their nuclear programs, with expectations ranging from 40 to 86 GWe of installed capacity in by 2020.

3.2 Response to Fukushima accident

The 2011 nuclear accident at the Fukushima Daiichi nuclear power plant in Japan brought a sudden halt to the worldwide enthusiasm for nuclear power. On March 16, five days after the accident, the State Council of China announced the suspension of approvals of new nuclear projects, and started comprehensive safety inspections of all existing nuclear projects, including those in operation and under construction as well as all research reactors and fuel cycle facilities. The State Council also suspended construction of four approved units on which work was to begin in 2011. The HTR-PM project in Rongcheng, Shandong province, though ready for the first concrete to be poured for its foundations, was also delayed.

In June 2012, after gaining approval of the State Council in principle, the National Nuclear Safety Administration (NNSA) released drafts of “Report on safety inspection of national civilian nuclear facilities” (hereafter referred to as “Safety Inspection Report”) and “The 12th Five-Year Plan for Nuclear Safety and Prevention and Control of Radioactive Pollution and the Long-term Vision by 2020” (hereafter referred to as “Nuclear Safety Plan”).[5]

- The Safety Inspection Report covered 11 nuclear safety areas, including site selection and external event evaluation; flood and earthquake resistance; extreme disaster prevention and protection; electricity blackouts and emergency plans; severe accident prevention and mitigation; environmental monitor systems; and emergency response system effectiveness.

- As concluded in the Safety Inspection Report, the operating reactors “basically fulfill” China’s nuclear safety laws and regulations and the International Atomic Energy Agency’s latest standards; The nation’s reactors are capable of responding to basic accidents and severe accidents as designed, and safety risks are found to be under control.

- The Safety Inspection Report also pointed out four major safety problems, including the lack of severe accident alleviation rules, the use of an improper design basis for flood, tsunami and earthquake protection, and the use of an insufficient safety margin in planning.[6]

- The Nuclear Safety Plan laid out short-, mid- and long-term tasks to strengthen safety for NPPs, research reactors and fuel cycle facilities. For example, short-term tasks for operating reactors included inspecting and waterproofing all openings, electric cable lines, etc.; and ensuring cooling functions are maintained for the reactor core and spent fuel in the event of a blackout through the use of mobile generators and pumps.

In October 2012, according to an official statement, the Executive Meeting of the State Council approved the “Nuclear Power Safety Plan (2011-20)” and “Mid- and Long-term Development Plan for Nuclear Power (2011-2020)”.[7] The statement said:

- China will also apply the world’s highest safety requirements to new nuclear power projects and adhere to third-generation nuclear safety standards in constructing new projects.

- During the 2011-2015 period, no nuclear projects will be constructed in inland regions, with construction allowed on only a few projects in coastal areas that have gone through adequate justification processes.

- China should constantly carry out safety upgrades on currently operating reactors and use the most advanced mature technologies.

On the same day, China also issued the 2012 edition of its Energy Policy White Paper, elaborating on its energy development policies, energy conservation and the promotion of renewable power sources. The white paper emphasizes that China will develop nuclear power in a safe and highly efficient way. China’s installed nuclear power capacity is expected to reach 40 GWe by 2015. Soon after the publication of the White Paper, China restarted the nuclear projects suspended after the Fukushima accident.

In March 2013, China Daily news reports indicated:[8]

- Nuclear power totaling 3.24 gigawatts (GWe) will be added in China in 2013.

- 30 units were under construction in China with a total capacity of 32.81 GWe.

- Installed nuclear capacity will total 58 GWe by 2020, accounting for less than 4 percent of China’s total power-generating capacity.

- An additional 30 GWe of nuclear units will be under construction as of 2020.[9]

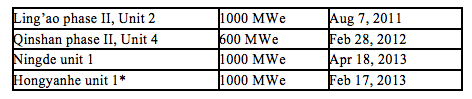

In terms of nuclear power capacity, four new units (3.6 GWe) have been brought into operation in China since the Fukushima nuclear accident, making the total nuclear capacity reach 13.9 GWe (17 units total) by mid-2013. Table 2 lists the recently added units:

Table 2: Recently Added Nuclear Units in China

*: date of first connection to grid

3.3 Nuclear regulation system

3.3.1 Governmental organizations related to nuclear power

Formally, three organizations are in charge of governing nuclear energy development in China.

The National Energy Agency (NEA) is under the National Development and Reform Commission. As the governmental department for Nuclear Energy, NEA is responsible for promoting the development of nuclear energy, drafting corresponding development plans, and organizing nuclear energy research.

The China Atomic Energy Agency (CAEA) is under the Ministry of Industry and Information Technology (MIIT). As the government department for nuclear industry, CAEA has the responsibility for development of China’s nuclear industry (except for NPPs), coordinating nuclear emergency management, and being the main contact with the IAEA on behalf of the Chinese government.

The National Nuclear Safety Administration (NNSA) of the Ministry of Environmental Protection (MEP) is the central government agency responsible for regulating nuclear safety, and for supervision of all civilian nuclear infrastructure in China. The NNSA also reviews nuclear safety activities and regulates the approval mechanism for those activities.

The present organization of the governing bodies for nuclear power in China, and the relationships between them, have been formed by a complicated set of historical factors, which might be difficult to understand for foreigners.

3.3.2 Regulation system

More than anything else, a proper regulation system is essential for safe development of nuclear energy. In short, China’s regulation system can be illustrated by the pyramid structure in Figure 1, containing laws and acts related to nuclear power, regulations, national standards, safety guides, and technical documents.

Figure 1: Nuclear Regulation System in China

In general, China develops its nuclear safety regulations to be based on the IAEA nuclear safety standards, while also including consideration of national conditions and regulatory practice. The technical goals, safety requirements and methods described in the regulations are consistent with the international safety standards. After the Fukushima accident, China initiated the preparation of the Atomic Energy Act and the Nuclear Safety Act in order to refine the general requirements for nuclear safety as described by law.

Licensing of nuclear facilities is at the core of regulation. In China, the NNSA is responsible for issuing licenses for design, installation, and construction of nuclear energy facilities, as well as licensing of radioactive waste management (from transportation to final disposal) facilities and other elements of the nuclear sector. As a regulator, the NNSA issues licenses to companies and individuals and undertakes the duty of conducting inspections.

Iv. SPENT FUEL STORAGE IN CHINA

4.1 Storage capacity at reactor

Dating from the start of operations of China’s first nuclear power plant, the total operational experience with nuclear power in China had reached only about 130 reactor years by 2012. The total discharged spent nuclear fuel in China as of the end of 2012 is estimated at around 2000 tHM, excluding the spent fuel from CANDU reactors.

Most spent PWR fuel is stored in pools on reactor sites. Generally, the on-site spent fuel storage capacity at operational nuclear power plants can accommodate 10 years of spent fuel. Taking into account ongoing trends in nuclear fuel management, such as increasingly high rates burnup, extensions of reload cycles, and high-dense pack storage in spent fuel pools into consideration, the storage capacity of present facilities can be enlarged to hold approximately 20 years’ worth of spent fuel. Currently, all PWR spent fuel is in fact stored at NPP sites except for part of the spent fuel from the Daya Bay NPP, the first NPP in commercial operation in China. Since 2003, thea load of spent fuel from Daya Bay has been transported approximately twice annually to the centralized interim storage facility in Gansu province. For detailed information on spent fuel in China’s NPPs, please see the analysis by Yun ZHOU.[10] Zhou’s analysis indicates that there is no urgent worry about the storage capacity in most China’s NPPs. However, the storage capacity in the spent fuel pools at Daya Bay and Tianwan might approach their limits within the next few years.

4.2 Spent fuel storage methods for different reactor models used in China

China’s nuclear fleet currently consists and will consist of multiple nuclear models from different manufacturers and of different designs. Models used in China include PWR units such as the M310, CPR, CANDU, and AP1000 designs, as well as high temperature gas reactors (HTR) and other reactor types. This variety of models in use makes for a large diversity of storage specifications for spent fuel at reactor sites. The typical storage methods used are discussed in this section.

4.2.1 M310/CPR1000

The M310 reactor type is a typical PWR with a net capacity of 900 MWe and a three cooling loop design. China imported two units of M310 from France in the early 1990s and installed them in the Daya Bay nuclear power plant. As the “improved Chinese PWR” and designated Generation II+ reactor, CPR 1000 is an upgraded version based on M310 technology. As of this writing, four CPR1000 units are already in operation at the Ling’ao NPP, and more than 30 are under construction or have been ordered in China. According to the national nuclear safety plan, all new reactors are required to meet Generation III safety standards. As a result, some additional safety measures or modifications will be implemented on CPR 1000 reactors to enhance their safety levels.

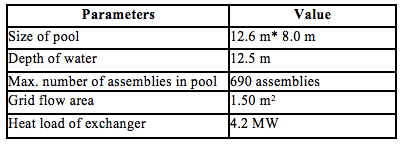

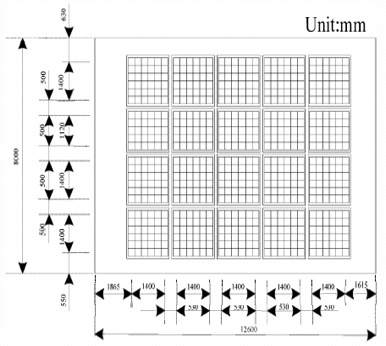

Spent fuel discharged from M310/CPR1000 reactors is stored in fixed racks arrayed in a storage pool. The total volume of water in the spent fuel pool for these reactor models is approximately 1300 cubic meters, with the overall dimensions and configuration as shown in Table 3 and Figure 3, below11. The storage pool can hold twenty racks, each of which can store 30 or 36 spent fuel assemblies. The maximum capacity of the spent fuel pool is 690 assemblies, equivalent to about 10 years of spent fuel generation. The thermal output of the spent fuel is transferred via circulation of the water in the pool through forced external heat exchangers. The decay heat is exchanged by two horizontal tube heat exchangers. The heating load of the external heat exchangers is 4.2MW.

Table 3: Spent Fuel Pool Parameters for M310/CPR1000 Reactor Types

Figure 2: Spent Fuel Pool Cross Section for M310/CPR100 Reactors[11]

4.2.2 AP 1000

The Westinghouse AP1000 is the main reactor model being used in China’s move to Generation III technology, and involves a major technology transfer agreement. The AP1000 is a 1250 MWe gross capacity reactor with two coolant loops. The first four AP1000 reactors in China are being built at the Sanmen and Haiyang sites.

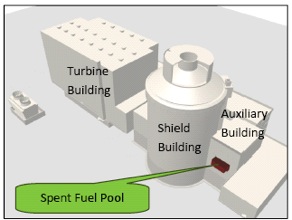

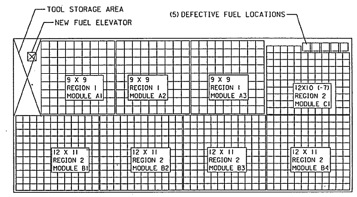

The location of the spent fuel pool in the AP1000 design is in the auxiliary building, which is adjacent to the shield building (see Figure 3, below).[12] As described in the AP1000 Standard Combined License, “The pool is approximately 42.5 feet deep and constructed of reinforced concrete and concrete filled structural modules. The normal water volume of the pool is about 181,000 gallons of borated water. Spent fuel is stored in a high-density rack that includes integral neutron absorbing material to maintain the required degree of subcriticality. The rack is designed to store fuel with a level of enrichment equal to the maximum design basis. Each fuel rack includes storage locations for 121 or 81 fuel assemblies. The spent fuel pool includes 889 assemblies with the layout of racks as shown in Figure 4.[13] The spent fuel pool can hold up to 10 years of discharged fuel plus fuel equivalent to the contents of one additional reactor core.

Figure 3: AP1000 Plant Layout of Spent Fuel Pool

Figure 4: AP1000 spent fuel pool layout

During normal and abnormal conditions, the active defense-in-depth and duty systems provide highly reliable spent fuel pool cooling. For unlikely events with extended loss of AC power (station blackout) and/or loss of heat sink, the AP1000 design provides for cooling requirements by passive means. Only simple or no-operator actions are required for cooling during the first 72 hours without power. For extreme events, the spent fuel pool spray system provides an additional line of defense to provide fuel cooling. Backup systems are provided through built in plant connections and pre-arranged off-site supply of emergency power and portable pumps. Water is available from plant storage, offsite and onsite service water (sea water)[14].

4.2.3 CANDU 6

Two CANDU reactors (1.2 GWe in total) are installed and in operation at the Qinshan Phase III nuclear power plant. The spent fuel discharge from the CANDU reactors is first stored in spent fuel pools for cooling. About 5000 spent fuel bundles are discharged per reactor per year. The capacity of the CANDU spent fuel pool is 37,728 bundles, equivalent to the number of bundles typically discharged in 7.6 years. Due to the high production of spent fuel per year (in terms of spent fuel mass) and the relatively low thermal density of the spent fuel discharged, it is the practice in China to remove CANDU spent fuel from pool storage and place it in a dry storage facility. CANDU spent fuel is considered to be a potential resource for reprocessing in the future.

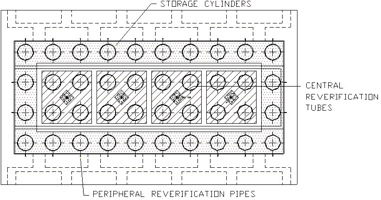

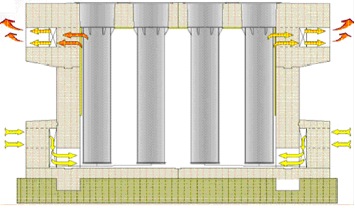

The construction of the dry storage facility in Qinshan Phase III started in 2008. The first two concrete MACSTOR-400 dry storage modules were completed in 2009. There are plans to construct 18 MACSTOR-400 modules at a rate of 2 modules every 5 years. Each module includes 24000 spent fuel bundles, which is the equivalent of 4.8 years of discharged spent fuel per unit at typical discharge rates. A diagram of a MACSTOR-400 module is shown in Figure 5, below. In this dry storage module, the decay heat of spent fuel is transferred by natural convention to the air, as shown in Figure 6.[15]

Figure 5: Diagram of MACSTOR-400 storage module

4.2.4 HTR-PM

The high temperature reactor pebble-bed module (HTR-PM) is considered to have many unique features associated with so-called “Generation IV” nuclear technologies, such as inherent safety, high outlet temperature (thus allowing high efficiency of electricity generation using a gas turbine) and other attributes. A 200 MWe demonstration reactor with pebble bed fuel and helium coolant is under construction in Rongcheng, Shandong province. The first concrete for the foundation of the HTR-PM reactor project was poured in December 2012. A thermal efficiency of 40%, a use of domestic materials of 75%, and a 50-month construction period for the first unit are envisaged.

The spherical fuel element of the HTR-PM has much higher burnup than PWR fuel, reaching 90 GWd/tU on average. Due to the large divergence between HTR and PWR fuel, the initial steps required for HTR spent fuel reprocessing will be completely different than for PWR fuel, and there is a lack of research on how HTR fuel might be reprocessed. As a consequence, dry storage facilities are expected to be used for HTR-PM spent fuel storage.

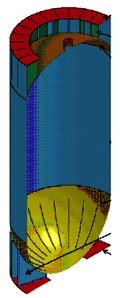

Spherical spent fuel elements from HTR-PM reactors are expected to be stored in stainless steel casks. A schematic diagram of a proposed storage cask for HTR-PM fuel is shown below (Figure 7). The cask is 4.18 m high, 1.74 m in diameter and has a wall thickness of 20 mm. Each cask is designed to hold about 40000 spherical fuel elements. Under regular operational conditions of the HTR-PM reactor, about 400 fuel elements are discharged per day, which means one cask would be filled each 100 days that the reactor operates. The storage facility designed for the reactor can hold 280 casks. Thus, the total capacity of dry storage is sufficient to accommodate all of fuel elements discharged from the core during the reactor’s lifetime. The maximum decay heat in one cask is 27.1 kW at the time when the cask is filled. Casks are vertically positioned in the storage facility. The facility has different storage zones to manage fuel elements that have been discharged from the reactor at different times. Based on the decay heat of the casks stored in the different areas, forced ventilation is provided for 30 to 60 months.[16]

Figure 7: Schematic Diagram of the Cask Design for HTR-PM Spent Fuel Elements Storage

4.3 Studies on the safety of spent fuel storage

Following the Fukushima accident, in addition to the above engineering research and development for storage for different types of spent fuel, some preliminary research activities on the safety of spent fuel storage have been conducted by different organizations in China.

The China Nuclear Power Engineering Co., Ltd. (CNPE) studied the safety features of Spent Fuel Pool (SFP) in GW-sized PWRs using Probabilistic Safety Analysis (PSA) methods. Eight groups of reactor events, including loss of coolant accidents (LOCA), loss of off-site power, loss of plant thermal cycling, and other events were taken into consideration. The summary conclusions of the research include an estimated frequency of spent fuel damage of 2.17*10-7 per reactor-year, which is quite low compared to the frequency of core damage[17].

Using a 1000 MWe PWR as an example, Zhen assessed the consequence of attack on a spent fuel pool by terrorists. The radii of areas in which under different levels of radiological risk were calculated using the MELCOR Accident Consequence Code System (MACCS).[18] The results show that in the three accidental cases in which 1) a Zircaloy fire propagates throughout all of the spent fuel in the pool, 2) a Zircaloy fire involves only the batches of spent fuel last removed from the reactor, and 3) radioactive substance releases occur only from the gaps among the last three discharged fuel batches, the radii of the areas in which there is danger of acute death are about 6 km, 3 km and 0 km respectively; the radii of areas in which the effective dose is larger than 50 mSv are about 80 km, 34 km and 9 km respectively; and the radii of the areas in which the avertable dose[19] if those exposed take shelter is larger than 10 mSv are about 100 km, 48 km and 11 km respectively.

V. Final remarks

Due to the country’s large population and rapid economic growth, electricity demand in China continues to grow at a high rate. Nuclear energy will play a more and more important role in China’s energy mix. After the shock of the Fukushima nuclear accident, the development of China’s nuclear sector has slowed somewhat but still continues at a steady pace, and with planned levels of new development in the nuclear sector that exceed those of any other nation. The nuclear installed capacity in China is projected to be 58 GWe in 2020.

Due to the present relatively small quantity of spent fuel currently in storage, it appears that there will be no critical pressure to reduce the quantities of spent fuel stored on-site at Chinese reactors in the near-term. In fact, except for Daya Bay, all of the existing nuclear plants in China are storing spent fuel exclusively in at-reactor storage. Wet pool storage of PWR spent fuel is a mature technology, and is widely implemented in all operational nuclear plants in China. Based on the technical details of the spent fuel pool technologies described in this paper, it seems that there are no serious risks associated with wet pool storage in China. Based on still-evolving enhanced safety regulations, there is no doubt that the safety standards for spent fuel storage will be strengthened further over time. The author of this paper believes that safety concerns regarding wet storage are not a sufficient motive to develop or deploy dry storage technology in the near future.

Dry storage is currently only used for CANDU reactors in China, and will be implemented for HTR spent fuel. These two reactor models account for only a minor portion of the whole Chinese nuclear fleet. But the utilization of dry storage and its performance will have a great impact on future decision-making for the sector. Though some experts consider that the pool capacity at reactors in China is large enough to accommodate spent fuel for the next 5 to 10 years, there are strong voices supporting the building of a large-scale centralized spent fuel storage facility soon. In part, it is argued, the current practice of pool storage for spent fuel in highly dense packed arrays has been subject to criticism following the Fukushima accident. In case dense-racking is ultimately not chosen as a means of spent fuel storage in China, the decrease in potential spent fuel storage density will result in a lack of storage space at Chinese reactors relatively soon. For at-reactor storage, it is difficult to build new pools to store spent fuel due to the complexity of the pool systems. Dry storage is very promising in those cases. For centralized storage away from reactors, dry storage is still a strong competitor to pool-type storage due to advantages such as low investment, modular design, and easy maintenance. As a result, though dry storage has not been adopted for PWR spent fuel storage in China, the utilization of dry storage facilities is a strong possibility in the short or medium-term.

VI. REFERENCES

[1] Phys,org, “China energy consumption rises 3.9% in 2012”, dated Feb 24, 2013, and available as http://phys.org/news/2013-02-china-energy-consumption.html.

[2] International Energy Agency (IEA, 2012), 2012 Oil & Gas Security, Emergency Response of IEA Countries: People’s Republic of China, available as http://www.iea.org/publications/freepublications/publication/China_2012.pdf.

[3] http://news.xinhuanet.com/english/china/2013-01/11/c_132096903.htm

[4] CIA World Factbook, 2012

[5] http://english.mep.gov.cn/News_service/news_release/201206/t20120621_231995.htm

[6] http://www.dynabondpowertech.com/en/nuclear-power-news/topic-of-the-month/30-topic-of-the-month/5935-problems-found-during-the-safety-inspection-of-civilian-nuclear-power-facilities

[7] http://news.xinhuanet.com/english/china/2012-10/24/c_131927898.htm

[8] http://usa.chinadaily.com.cn/china/2013-03/12/content_16301751.htm

[9] Hua LIU, presentation in ICONE 13, July 30, 2013. Chengdu, China.

[10] Zhou Yun (2012), An Initial Exploration of the Potential for Deep Borehole Disposal of Nuclear Wastes in China, Nautilus Institute Special Report dated October 23, 2012, and available as https://nautilus.org/napsnet/napsnet-special-reports/an-initial-exploration-of-the-potential-for-deep-borehole-disposal-of-nuclear-wastes-in-china/#axzz2UNmkAn6g.

[11] WANG Kuo, GUO Yun,et al. Spent Fuel Pool Transient Analysis under Accident Case and the Flow Establishment Process of Passive Cooling System. 2011 China located International Conference on Information Systems for Crisis Response and Management

[12] Luca Oriani (2012), “Extreme Events: AP1000 Safety Concepts and Robustness to External Hazards”, available as http://www.las-ans.org.br/pdf%202012/Luca%20Oriani.pdf

[13] AP1000 Standard Combined License Technical Report: Spent Fuel Storage Racks Criticality Analysis. APP-GW-GLR-029. available as: pbadupws.nrc.gov/docs/ML0618/ML061840539.pdf

[14] John Giddens, et al. (2012), “AP1000 Safety Concepts and Robustness to External Hazards”, available as pbadupws.nrc.gov/docs/ML1211/ML12116A298.pdf

[15] Hui ZHAO, master degree dissertation in Shanghai Jiaotong University, 2007

[16] Y. F. Huang, master degree dissertation of Tsinghua University, 2012

[17] Presentation of CNPE, Oct. 2012, available as: http://ishare.sina.cn/dintro.php?id=35130415

[18] Q. Y. Zheng, et al. “Consequence Assessment of Attacking Nuclear Spent Fuel Pool By Terrorist”. Radiation Protection (in Chinese), Jan. 2005.

[19] The IAEA defines “avertable dose as “[t]he dose that could be averted if a countermeasure or set of countermeasures were to be applied”. See http://www.iaea.org/ns/tutorials/regcontrol/intro/glossaryd.htm. .

VI. NAUTILUS INVITES YOUR RESPONSES

The Nautilus Peace and Security Network invites your responses to this report. Please leave a comment below or send your response to: nautilus@nautilus.org. Comments will only be posted if they include the author’s name and affiliation.