DAVID VON HIPPEL AND PETER HAYES

FEBRUARY 6, 2019

I. INTRODUCTION

In this essay, David von Hippel and Peter Hayes conclude that the single gasification unit imported from China to convert coal to oil “could be used to produce synthetic fuels in volumes on the order of 10 percent of recent DPRK petroleum supplies.”

David von Hippel is Nautilus Institute Senior Associate. Peter Hayes is Director of the Nautilus Institute and Honorary Professor at the Centre for International Security Studies at the University of Sydney.

A downloadable PDF file (1.4MB) of this report with higher resolution graphics is here.

The views expressed in this report do not necessarily reflect the official policy or position of the Nautilus Institute. Readers should note that Nautilus seeks a diversity of views and opinions on significant topics in order to identify common ground.

This report is published under a 4.0 International Creative Commons License the terms of which are found here.

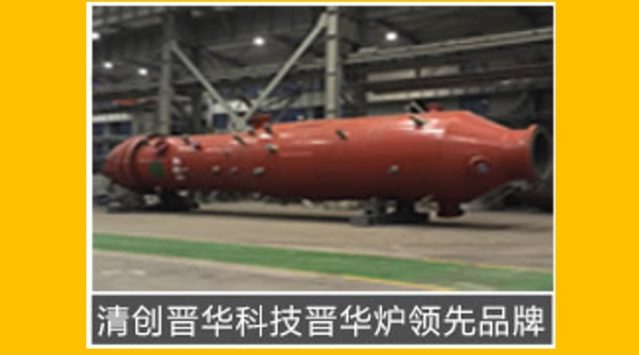

Banner image: Gasification device using Jinhuagong furnace coal gasification technology, Cylon Engineering Co., Ltd, supplier to DPRK, from here.

II. NAPSNET SPECIAL REPORT BY DAVID VON HIPPEL AND PETER HAYES

DPRK INVESTMENTS IN COAL GASIFICATION DRIVEN BY LONG-RUN JUCHE AND SANCTIONS PROOFING

FEBRUARY 6, 2019

Overview

We have argued previously that the DPRK could adopt various strategies to blunt the impact of United Nations Security Council (UNSC) oil import sanctions in the short-to-medium-term.[1] But, in the longer-run, assuming the sanctions regime is effective in cutting off the bulk of prohibited oil imports, we suggested that DPRK would actively develop alternative sources of fuel, particularly for its transport sector. Although the DPRK is reported to have modest oil and gas resources, most of these are offshore resources not yet tapped, and though on-shore oil production has been reported in the past, it has never been significant, and it is unclear if it has continued.

The one fossil fuel resource that the DPRK has in abundance- is coal—perhaps 15 billion tonnes of anthracite and lignite.[2] Although useful to run power plants and factories, and for space heating in structures large and small, few modern economies make substantial use of coal to fuel vehicles and for other uses—such as diesel generators—generally requiring liquid fuels, due to the costs of converting coal to oil product substitutes.

However, this barrier does not mean that coal cannot be converted to liquid fuels. Historically, coal was a source of “town gas” used for cooking, heating, lighting, and industry in towns and cities throughout Europe, North America, and elsewhere from the 1800s through the early 1900s, and was phased out only when natural gas became widely available. More recently, two nations—Germany during World War II and apartheid South Africa—have, when isolated from normal trade in crude oil and oil products, turned to making synthetic liquid fuels from coal.[3] Recent reports suggest that the DPRK, through investments in coal gasification and related technologies, has been planning for some years to implement systems to produce liquid fuels and other products from coal as substitutes for liquid petroleum fuels.[4] These investments in coal gasification and in using the “syngas” thus produced to make liquid fuels represent a long-term pathway to making the DPRK more resilient to UNSC sanctions, and have implications for how the international community should address the DPRK’s nuclear weapons issue, which is, as we have argued, intimately entwined with DPRK energy insecurity.

Making Gaseous and Liquid Fuels from Coal

Like oil and gas, coal is a fossil fuel composed of hydrogen and carbon, as well oxygen, nitrogen, sulfur, and other trace components. Crude oil is a mixture of hydrocarbons—compounds mostly composed of carbon and hydrogen, and oil refineries are used to fractionate this mixture into lighter products—shorter-chain hydrocarbons—such as propane, gasoline, diesel oil, and kerosene, and heavier products such as residual fuel oil and asphalt.[5] Natural gas is mostly composed of methane (CH4), typically with smaller concentrations of hydrocarbon gases such as ethane, propane, and butane, plus some carbon dioxide and nitrogen. Coal is composed largely of hydrocarbons in solid form. With the application of heat, steam, and the right amount of oxygen, the hydrocarbons in coal can be broken into chemical components that can be used as a gaseous fuel, in manufacturing, and/or to make liquid fuels.

Gasification

Gasification is a process whereby coal, or other sources of carbon and hydrogen including biomass, are heated to 800 to 1800 degrees C in a reactor in which the input of air (or pure oxygen) is controlled so as to yield partial combustion of the fuel source.[6] With the addition of steam (water in gaseous form) gasifiers produce a stream of synthesis gas, or “syngas”, that is composed mainly of hydrogen (H2) and carbon monoxide (CO), along with tars and other byproducts. Gasifiers can be built in a variety of different configurations, with the choice of configurations based in part on the input fuels to be used and output fuels to be produced, of and in sizes ranging from quite small to major industrial installations. On the smaller end of the scale, for example, gasifiers are used to power some trucks in the DPRK, where reactors fueled with coal and/or biomass sit on the bed of trucks and produce gas that is used in the truck’s internal combustion engine. These trucks have been spotted by many visitors to the DPRK (including the authors), and are reputedly more prevalent in DPRK locales and at times when petroleum products are scarce, although they are a minority of the truck fleet.

Coal to Liquids and Other Products

The stream of syngas that is the output of a gasifier can be used directly as a fuel for boilers and other sources of heat/steam, or can be used as an input feed to make other chemicals. CO and H2 can be used along with other inputs, such as steam, as feedstocks for a variety of industrial processes, including production of methanol, inputs to plastics production, and synthetic motor fuels. Synthetic motor fuels could be produced from syngas through the Fischer-Tropsch process, which has been in use since the 1930s, and was used extensively in Nazi Germany during the war years. This method of producing liquid fuels from coal is known as indirect coal liquefaction (ICL). In ICL, a variety of chemical reactions are used to convert CO and hydrogen into methane and longer-chained hydrocarbons, including fuels and inputs to other types of manufacturing, such as of chemicals, plastics and synthetic fiber. Hydrogen can be used with nitrogen from the air and/or the nitrogen present in coal to produce nitrogen fertilizers such as anhydrous ammonia (NH3) or urea.

An alternative route from coal to liquid fuels is called direct coal liquefaction, or DCL.[7] DCL uses solvents at temperatures of 400 to 500 C and pressures of several hundred atmospheres to dissolve the hydrocarbon components of coal in a solvent, creating a slurry which is then refined in a facility akin to an oil refinery. Although DCL produces higher yields of oil per tonne of coal, the products of DCL are difficult to refine (being a more complex mixture than the composition of crude oils). A number of different technical approaches have been taken to DCL, which has been the topic of considerable research since the 1970s,[8] but DCL has proven a difficult technology to bring to commercial maturity.

Coal Gasification in the DPRK

The DPRK is not a newcomer to the technology of gasification. Lacking significant oil resources, in the 1960s and 1970s the DPRK turned to the use of coal, via gasification, as a source of hydrocarbons to produce a polyester-like fabric called “vinylon” and as a base for making nitrogenous fertilizers, as well as to power the fleet of trucks described above.[9]

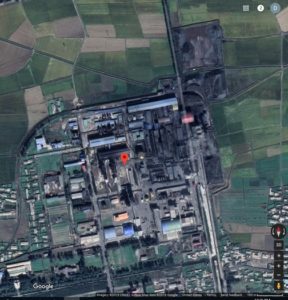

A major center for the production of fertilizers and textiles is the industrial city of Hamhung on the DPRK’s east coast, the “Feb. 8 Vinylon Union Enterprise” (a rough translation of 2월 8일 비날론 연합기업소”) and the Heungnam Union Fertilizer Company (흥남 비료연합기업소) are located in the city of Hamhung, on the DPRK’s east coast. Satellite photos of these facilities are shown in Figure 1 and Figure 2. Plumes of smoke, piles of coal, and refurbished roofs on many buildings suggest that both of these factories remain active.

Figure 1: Feb. 8 Vinylon Union Enterprise, in Hamhung, DPRK (source, Google Maps, photo taken probably in the summer of 2018)

Figure 2: Heungnam Union Fertilizer Company, in Hamhung, DPRK (source, Google Maps, photo taken probably in the summer of 2018)

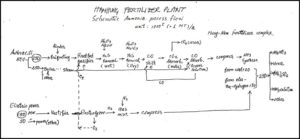

Figure 3 provides a schematic of the ammonia fertilizer production process at the Hamhung Fertilizer Plant as of 1993. The presence and active use of gasifier technology in instances such as this, back to the 1990s and before, suggests a long-term interest in this technology on the part of North Koreans. Originally, this interest in coal gasification was driven by the DPRK’s juche, principle of self-reliance, not external sanctions. More recently, however, the impetus towards gasification appears to have switched to be primarily sanctions-driven, though reinforcing the DPRK’s tendencies toward juche-driven technological choices. These choices can often run counter to what might be chosen on, for example, purely economic and/or environmental bases, but are understandable responses to the DPRK’s ecnomic and political circumstances.

Figure 3: Schematic of Gasifier-based Ammonia Production Process at Hamhung Fertilizer Plant[10]

More recently, various reports have focused on gasifier and related development at the Namhung Youth Chemical Complex, located near the west coast city of Anju (and, coincidentally, about 16 km south of the DPRK’s nuclear research center at Yongbyon). Although the industrial area itself dates from the late 1960s and early 1970s, since at least the mid-2000s, the Namhung Youth Chemical complex has been a focus of the installation of gasification equipment to process coal into a variety of chemicals, including fertilizer and fiber.[11] Satellite imagery over time, as described by 38 North, has shown installation of gasification equipment and related infrastructure at the site, and the recent satellite image below (Figure 4) shows piles of coal, an apparent waste pond partially filled with what appears to be coal ash, and smoke from a stack, all indicating recent and ongoing operation.

Figure 4: Namhung Youth Chemical Complex, Near Anju, DPRK (source, Google Maps, photo taken probably in the summer of 2018)[12]

Even more recently, reports have shown DPRK leaders including Kim Jong Un visiting a site called the “Sunchon Chemical Complex”, where the DPRK is installing a “C1 Chemical Complex”. The “C1” refers to the use of gasification of coal to produce syngas, with the carbon monoxide and hydrogen then used as the basis for the production of a variety of chemical products, “from synthetic fuels for the transport industry to key industrial chemicals and agricultural inputs.”[13] A 2017 press release by China’s Jinhua Technology Ltd., describes a gasifier system being (at the time) produced for the Sunchon complex as follows:

“The North [Sunchon] Chemical Plant plans to build a 40,000 Nm3/h (CO+H2) syngas gasification unit in [Sunchon], North Korea. The project uses anthracite from [Sunchon], North Korea as a raw material, and the product is methanol. The gasification unit adopts Jinhua furnace coal gasification technology, and Saiting Engineering Co., Ltd. (formerly the Second Design Institute of the Ministry of Chemical Industry) carries out engineering design.

The effective gas production in the gasification boundary area of this project is 40,000 Nm3/h (CO+H2), and the gasification pressure is 4.0 MPaG. One gasification furnace is not ready. The single furnace produces an effective gas of 40,000 Nm3/h (CO+H2), and the gasifier waste by-product produces 4.5 MPaG saturated steam 40t/h.

The raw material of the gasifier is anthracite, the concentration of coal slurry is 62%, and the melting point of ash is 1490 °C.

The project is under construction and is scheduled to go into production in 2019.”[14]

We do not know exactly where this project will be sited. The photo shown in Figure 5, about 2 km east of the city of Sunchon and just north of the site of an old Sunchon Vinylon Complex,[15] however, appears to have a mixture of older buildings and new facilities, such as the red chemical or oil storage tanks at the bottom left of the photo, plus rail facilities and ongoing coal combustion of some kind (as shown by the white smoke in the upper middle of the photo), that would make it a candidate site for the new/refurbished chemical plant.

Figure 5: Possible Location of North Sunchon Chemical Plant (source, Google Maps, photo taken probably in the summer of 2018)[16]

The Wall Street Journal article cited above notes contacts, including visits of North Korean delegations to Chinese companies that export gasification equipment, and trades between the DPRK and China and, in one instance, reported export of Russian coal-to-liquids technology to the DPRK.[17] The article and other reports indicate that the DPRK has also, in recent years, worked to substitute oil product use in, among other industries, cement and iron and steel manufacture, with a view towards greater energy self-sufficiency.[18]

Implications of the DPRK’s Push for Gasification

Our rough estimate suggests that the reported output of the gasifier destined for the North Sunchon Chemical Plant could be used to produce synthetic fuels in volumes on the order of 10 percent of recent DPRK petroleum supplies (or about 15 percent of our estimates of 2010 crude oil and oil products imports by the DPRK. These outputs would be achieved with coal inputs equivalent to a percent or two of recent DPRK domestic production, which represents a certainly manageable level of increased coal output and/or a shift in the destination of coal no longer exported to China as a result of UNSC sanctions on coal exports.[19] Table 1 shows the assumptions, sources, and calculations used in our estimate of the output of the gasifier being imported for the North Sunchon complex.

Table 1: Conversion of Reported Sunchon Gasifier Output Units to Estimated Equivalent in Oil Products Energy Content

As such, the project appears to provide a significant benefit to the DPRK, in terms of supplying fuels to compensate for petroleum product imports that run afoul of United Nations Security Council sanctions passed in the last two years, although the project will not completely replace all lost imports on its own. In addition, some or even much of the production of this plant may be geared toward more efficient production of chemical precursors and other intermediate and final products now made in the DPRK from coal, not oil, so not all of the output of the gasifier will directly displace oil use.

Still, this installation is emblematic of the DPRK’s overall efforts to adapt not just to recent sanctions, but in general to its decades of relative isolation from the international economy. Essentially, the DPRK has developed over time and is continuing to develop a spectrum of adaptation strategies, ranging from the social and economic to the technical, and in scale from very small (personal or household) to large (industrial), to provide goods and services. The adoption of gasification, of which the reported installation is one of several that have been described over the last decade, is at the technical and large end of this spectrum, but it is just one of many adaptation strategies in use that will likely blunt the impact of sanctions.

Conclusions

The DPRK has always, based on our understanding, used coal to make many products (fertilizer and fiber among them) that most industrialized nations use natural gas or oil to make, so some or much of the new coal gasification may not be displacing much in the way of oil products (or replacing oil products unavailable due to sanctions). More likely is that much of the new gasification simply helps to increase output at existing industries, such as the steel and cement plant upgrades noted above. Our previous estimates have been that DPRK industries have not in recent decades used great deal of oil. Some naptha seems to be used (or have been used) as a fertilizer feedstock, and some heavy fuel oil is used in the cement and magnesite industries, but the latter could probably have been pretty easily displaced by coal (and there are limited uses for heavy fuel oil in the DPRK).

Producing liquid fuels from coal, whether by indirect or direct coal-to-liquids approaches (the latter a much less mature technology), would be an interesting addition to the DPRK’s energy repertoire, but on a large scale it would likely take years to implement. Moreover, these technologies are often, largely because they use coal as a feedstock, relatively polluting and inefficient ways of producing motor fuels,[20] and as a result are somewhat of a “last resort” for fuels supplies, which is why they are of interest to the DPRK, given the DPRK’s lack of access, for economic and geopolitical reasons, to other sources of liquid fuels.

Nonetheless, with patience (which North Koreans have, in our experience, in abundant supply), with some access to technology through outside partners such as China and Russia, and though the use of local resources and skills, the DPRK can be expected, if the current stalemate in relations continues, to develop substitutes for oil-based fuels. Although not a small undertaking, it seems possible that facilities could be assembled within the next five years or so to produce coal-based oil product substitutes in sufficient quantity to keep the DPRK economy going at its recent pace, although we would be surprised if fuel supplies would be sufficient to bridge the significant gap between what is supplied now and what the DPRK might be consuming if its economy were fully opened (that is, for a rapidly growing economy).

What this apparently ongoing (or at least begun) slow-but-steady replacement on the part of the DPRK of oil-based fuels with coal-based substitutes, together with the other “work-arounds” to reduce sanctions impacts, ultimately means is that the international community may find that it has progressively less leverage on the DPRK via sanctions as time goes on. As a result, we believe engagement as currently in play between the DPRK and ROK, and possibly between the DPRK and US, pending the results of the upcoming Summit discussions between U.S. President Donald Trump and DPRK Chairman Kim Jong Un, is therefore required to make true progress on the DPRK denuclearization issue.[21] Energy insecurity, as we have previously argued, is a root cause of the DPRK’s pursuit of nuclear weapons technologies. The international community’s leverage over the DPRK’s energy supplies will abate as the DPRK develops indigenous oil product substitutes. As a result, deals on denuclearization with the DPRK will, all else being equal, be harder to reach the longer true engagement discussions are delayed.

III. ENDNOTES

[1] See Peter Hayes and David von Hippel (2017), SANCTIONS ON NORTH KOREAN OIL IMPORTS: IMPACTS AND EFFICACY, NAPSNet Special Reports, September 05, 2017, https://nautilus.org/napsnet/napsnet-special-reports/sanctions-on-north-korean-oil-imports-impacts-and-efficacy/, and David F. von Hippel and Peter Hayes (2017), IMPACT OF UNSC RESOLUTION 2375 ON DPRK OIL IMPORTS, NAPSNet Policy Forum, September 12, 2017,

[2] See, for example, David von Hippel and Peter Hayes (2012), Foundations of Energy Security for the DPRK: 1990 – 2009 Energy Balances, Engagement Options, and Future Paths For Energy and Economic Development, dated September 13, 2012, and available as

https://nautilus.org/wp-content/uploads/2012/12/1990-2009-DPRK-ENERGY-BALANCES-ENGAGEMENT-OPTIONS-UPDATED-2012_changes_accepted_dvh_typos_fixed.pdf; and David von Hippel and Peter Hayes (2014), An Updated Summary of Energy Supply and Demand in the Democratic People’s Republic of Korea (DPRK), NAPSNet Special Reports, April 15, 2014, available as https://nautilus.org/napsnet/napsnet-special-reports/an-updated-summary-of-energy-supply-and-demand-in-the-democratic-peoples-republic-of-korea-dprk/.

[3] The company Sasol in South Africa continues to operate a large commercial coal-to-liquids plant, using high-ash-content domestic coal to produce fuels. See, for example, “Sasol produces 1,5 billion barrels of synthetic fuel from coal in fifty years”, dated August 24, 2005, and available as https://www.sasol.com/media-centre/media-releases/sasol-produces-15-billion-barrels-synthetic-fuel-coal-fifty-years.

[4] Jeremy Page (2018), “North Korea Turns Coal Into Gas to Weather Sanctions: Isolated regime transforms an abundant resource to survive curbs on oil imports”, Wall Street Journal, December 17, 2019, available as https://www.wsj.com/articles/north-korea-squeezes-its-coal-to-outlast-sanctions-11545067376?mod=searchresults&page=1&pos=1.

[5] Most modern refineries also use catalytic “crackers”, which are reactors in which the longer-chain hydrocarbons components of crude oil, such as heavy oils, are converted (“cracked”) into lighter (and typically more valuable) products such as gasoline and diesel. Crackers use heat, pressure, catalysts, and sometimes hydrogen to produce shorter-chain molecules.

[6] A summary description of gasification technologies is provided in the International Energy Agency/Energy Technology Systems Analysis Programme (IEA/ETSAP, 2010) document “Syngas Production from Coal”, IEA ETSAP – Technology Brief S01, dated May 2010, and available as http://large.stanford.edu/courses/2013/ph241/kallman1/docs/estap.pdf.

[7] For a concise description of ICL and DCL, see IEA/ETSAP (2010), “Liquid Fuels Production from Coal & Gas”, Technology Brief S02, dated May 2010, and available as https://iea-etsap.org/E-TechDS/PDF/S02-CTL>L-GS-gct.pdf.

[8] Research on DCL in the US and elsewhere remains ongoing—see, for example, Satya P. Chauhan, Daniel B. Garbark, and Rachid Taha, and Rick Peterson (2017), DIRECT COAL-TO-LIQUIDS (CTL) FOR JET FUEL USING BIOMASS-DERIVED SOLVENTS, Battelle, Inc., dated September 2017, and available as https://www.osti.gov/servlets/purl/1396265.

[9] See, for example, Charles Kraus, Evan Pikulski (2017), “The Coal Hard Truth”, dated February 27, 2017, and available as https://www.wilsoncenter.org/blog-post/the-coal-hard-truth.

[10] Schematic provided to P. Hayes during a 1993 Global Environment Facility (GEF) project mission to the DPRK on climate change mitigation, and included in the November 1993 Report on Global Environment Facility Mission to the Democratic Peoples’ Republic of Korea, prepared by Nautilus Institute for the United Nations Development Programme/GEF. The DPRK proposed to the GEF that it fund the February 8 Vinalon plant in Hamhung to import a German plasma-furnace technology operating at very high temperatures to convert pulverised brown coal mixed with hydrogen gas directly into suitable acetylene feedstock for vinyl production. The GEF mission judged that this project was not replicable nor economic, and did not recommend it for GEF consideration at the time.

[11] See Joseph S. Bermudez Jr. (2014), “North Korea’s Namhung Youth Chemical Complex: Seven Years of Construction Pays Off”, 38 North, dated April 10, 2014, and available as https://www.38north.org/2014/04/jbermudez041014/. See also, North Korean News, (2018), “Namhung Youth Chemical Complex”, dated November 15, 2018, and available as https://www.nkpulse.com/2018/11/15/namhung-youth-chemical-complex/.

[12] Approximate location, 39°39’24.7″N 125°41’44.8″E.

[13] See Hamish Macdonald (2017), “Could N. Korea’s C1 Chemistry industry enhance its self-sufficiency?

North Korea seeks to generate synthetic fuels and other products”, NK News, dated June 14th, 2017, and available as https://www.nknews.org/2017/06/could-n-koreas-c1-chemistry-industry-enhance-its-self-sufficiency/.

[14] Rough Google translation of Bei Jing Qing Chuang Jin Hua Technology Co., Ltd., (2017), “朝鲜顺川40000Nm3/h (CO+H2)气化装置”, ”North Korea Shunchuan 40000Nm3/h (CO+H2) gasification unit)”, dated May 10, 2017. And available as http://jinhualu.com.cn/?c=articles&a=show&id=116.

[15] As described in NK Economy Watch (2011), “The short life of the Sunchon Vinalon Complex area”, updated May 31, 2011, and available as http://www.nkeconwatch.com/2010/05/25/the-short-life-of-the-sunchon-vinalon-complex/.

[16] Approximate location from Google Maps, 39°24’43.4″N 125°59’28.8″E.

[17] The Russian SPEC reported (available as http://www.spbec.ru/upload/The%20technology%20of%20direct%20liquefaction%20of%20coal.pdf that it exported a direct coal liquefaction unit based on a “pulse high-voltage discharge” technology to a buyer in Nampo.

[18] For example, see the KCNA article and Youtube video (2013), “New Technology in North Koreas Chollima Steel Complex”, dated February 26, 2013, and available as https://www.youtube.com/watch?v=Sg38d5hFH40; Steel News (2018), “Kim Chaek Iron and Steel Complex completed Juche-Oriented Iron-making Production Process”, dated 27 September 2018, and available as https://steelguru.com/auto/kim-chaek-iron-and-steel-complex-completed-juche-oriented-iron-making-production-process/521838?type=steel; and Korea Today (2017), “By Their Own Technology and Resources”, Issue Number 11, pages 14-15, available as http://www.bannedthought.net/Korea-DPRK/KoreaToday/2017/KoreaToday-2017-11-OCR.pdf.

[19] A discussion of the DPRK’s likely response to sanctions on its coal exports can be found in David von Hippel and Peter Hayes (2017), DPRK COAL EXPORTS TO CHINA UNDER NEW UN SANCTIONS: POTENTIAL IMPACTS AND “WORK-AROUNDS”, NAPSNet Special Reports, February 14, 2017, https://nautilus.org/napsnet/napsnet-special-reports/dprk-coal-exports-under-new-un-sanctions-potential-impacts-and-work-arounds/,

[20] The combination of the efficiency penalty in having to use heat to break the molecules in coal apart to produce liquid and gaseous fuels, plus the greater amount of carbon contained in coal per unit heat content to begin with, means that coal-to-liquids invariably involves higher greenhouse gas emissions than simple refining of oil to produce oil products. Although there are schemes under which carbon can be captured from coal-to-liquids processes (typically with a cost and energy efficiency penalty), and ways in which the waste heat from these processes are and would be used for electricity generation and other uses, net greenhouse gas emissions are highly likely to increase if the DPRK embraces coal-to-liquids to a significant degree.

[21] For a general discussion of DPRK energy insecurity, engagement, and related issues, see David F, von Hippel and Peter Hayes, ENERGY INSECURITY IN THE DPRK: LINKAGES TO REGIONAL ENERGY SECURITY AND THE NUCLEAR WEAPONS ISSUE, NAPSNet Special Reports, December 28, 2017, https://nautilus.org/?p=47765.

IV. NAUTILUS INVITES YOUR RESPONSE

The Nautilus Asia Peace and Security Network invites your responses to this report. Please send responses to: nautilus@nautilus.org. Responses will be considered for redistribution to the network only if they include the author’s name, affiliation, and explicit consent

21 thoughts on “DPRK INVESTMENTS IN COAL GASIFICATION DRIVEN BY LONG-RUN JUCHE AND AND SANCTIONS PROOFING”